Qualifying a Contractor’s Safety Standards

Safety on the job-site is a very important aspect of working with a contractor. There are many ways that accidents can be avoided but the first place to start is when selecting your contractor. Whether it is a board meeting or a contractor interview you should always ask how your contractor approaches safety. Always make sure you are working with a company that has OSHA Trained employees. Here is a checklist of different types of safety topics to go over and question your contractor about.

1.) Certifications

Aerial Lift Certification: If the contractor is using aerial lifts on your job, your contractor should have received in-depth instruction on aerial lift equipment where their employees get hands-on training and classroom instruction about the different types of aerial lifts.

Swing Stage Certification: When swing-stages are being used, contractors need to have knowledge on how to monitor and maintain weight and ballast by properly testing the strength of the rigging before the swing stage is in use. Additionally the operators must be properly trained to harness themselves while operating the equipment on your property.

OSHA Certification: OSHA certification should be proctored to all employees by an OSHA Certified Trainer. This is industry standard, if your contractor doesn’t have this, then you need to dismiss them from the job. All employees need to be trained on the proper ways to navigate and communicate on a job-site in order to keep everyone on the property safe.

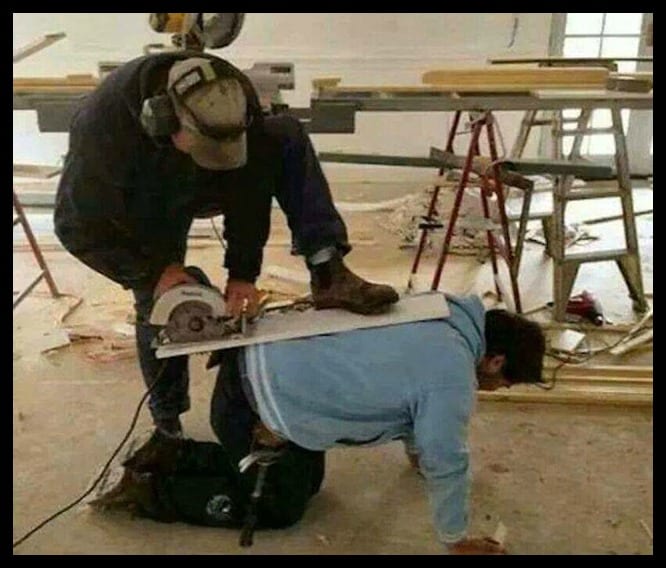

2.) Personal Protective Equipment

When discussing Personal Protective Equipment (PPE) with your contractor, make sure to address the risks and hazards that exist on the job site. This will explain what type of equipment is needed and why. Each employee should be trained when, how, and why to use each piece of protective equipment, especially how to store and maintain the equipment. Finally, you should ask how their program is monitored to insure every employee is wearing their equipment. The last thing you want, as a customer, is for your contractor to be issued a citation by OSHA and shut your project down. This is why it is important to know the effectiveness of their safety program so you can judge how safe the contractor actually is on-site.

3.) “Tool Box Talks”

On-site Safety Meetings at the beginning of each day are commonly referred to as “Tool Box Talks.” These are vital in order to keep safety “top of mind presence” while on the job-site. One common exercise is to have every employee that is a part of the meeting write a “safety practice” and turn it in to the foreman before they leave the meeting.

4.) Training & Experience

Above, we talk about working with contractors who have received OSHA Training, it is important to know the process involved in training employees. A typical question we get asked during the Contractor Interview is, “How do you train your employees?” The answer for us is easy…We have an employee orientation at the beginning of every year. We use this as a “team building” exercise as well as a time to educate all of our painters and carpenters on job-site safety,certifications, OSHA rules and regulations, etc.. Additionally, we have an on-boarding process for all our employees that may be hired mid-year, which gets them up-to-date in order to work on a job-site at our standard.

Always ask “How do you train your employees on safety?” this is the easiest way to find out if you are working with a company who is responsible and ready to take on a large project with many moving parts.

Recent Comments